KEY FEATURES

🔹 Disc Position Indicator

Clearly marked indicator on the shaft top allows easy identification of disc position at any time.

🔹 Hardened Disc Surface

Standard discs are reinforced with Stellite weld overlay or hard chrome plating, delivering high durability, superior wear resistance, and extended service life.

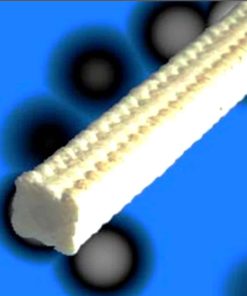

🔹 Anti-Leakage Seat Overlay Design

A multi-layer soft graphite overlay is embedded directly into the valve body, reducing wear and minimizing leakage.

Graphite is positioned in a grooved seat for easy maintenance and replacement.

Optional: multi-layer or solid metal seats also available

🔹 Dust Protection Design

Special bushing assembly prevents any foreign particles or contaminants from entering the shaft area.

🔹 Enhanced Shaft Strength

Shaft features special grooved design — eliminating the need for taper pin drilling and increasing strength and reliability.

🔹 Explosion Protection

Both shaft stop pin and bottom cover are engineered for high-level explosion safety compliance.

🔹 Easy Maintenance Disc

Pinless disc design simplifies disassembly and maintenance.

🔹 Bidirectional Sealing Design

Floating self-adjusting sealing mechanism with elliptical contact surfaces ensures zero leakage only when in the fully closed position.

For flanged-end valved, shaft positioning on the flange side helps reduce external leakage caused by ambient temperature fluctuations.

TECHNICAL SPECIFICATIONS

🔸 Design & Pressure/Temperature Ratings

-

ASME B16.34

-

API 609

🔸 Pressure Test Standards

-

API 598

-

ISO 5208

🔸 Flange Drilling Standards

-

ASME B16.5 / ASME B16.47

-

ISO 7005 / EN 1092

🔸 Mounting Flanges

-

ISO 5211

🔸 Face-to-Face Dimensions

-

API 609

-

ISO 5752

-

ASME B16.10

🔸 Fire Safe Compliance

-

API 607

-

ISO 10497

🔸 Low Emissions Standards

-

ANSI/ISA-SP-93

-

ISO 15848

-

TA LUFT

🔸 Cryogenic Applications

-

BS 6364

🔸 Product Marking

-

MSS-SP-25

-

ASME B16.34

🔸 Leakage Class

-

ANSI FCI 70-2 Class V

-

ISO 5208 Rate A

🔸 Quality Assurance

-

ISO 9001

-

PED 2014/68/EU (Module H)

-

ATEX 2014/34/EU

-

SIL 3 (suitable for safety systems up to SIL 2 in low demand mode; compliant for SIL 3 in redundant architectures)

🔸 International Certifications

-

API 609 Monogram

-

API 607

-

ISO 15848

-

ISO 10497

-

TR CU 010

-

TR CU 032

TYPICAL APPLICATIONS

-

Petrochemical industry

-

Thermal & cogeneration power plants

-

Steel plants

-

Oil refineries

-

Cryogenic environments

-

Pulp & paper industry

-

Nuclear power sector

Tiếng Việt

Tiếng Việt